|

|

Specialized Gears

In addition to the standard shaped gears, there are lots of other ones which will

enable you to build varied Technic models.

|

Crown

Gear Crown

Gear

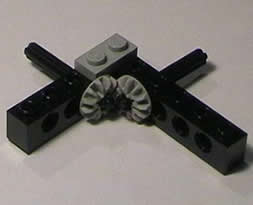

This gear is so called because the edges of it turn upwards like a crown. It is

the same size as a standard sized 24-tooth gear, but its unusual teeth shape allow

you to mesh it with other gears at right angles. The disadvantage of a gear like

this is that is will provide a lot of friction and must be backed up against a

beam or bushing to stop it slipping out of place. Despite this, it is still an

important gear and very useful. It can be used in place of a normal 24-tooth gear

but this is not advisable.

- The Crown gear meshed with a small, 8 toothed gear.

|

|

Bevel

Gear Bevel

Gear

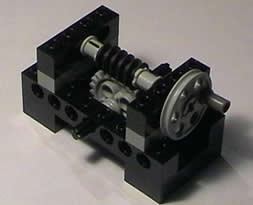

This gear is like the second incarnation of the Crown Gear, but it still has some

differences. The first, and most important, is that it can only mesh with other

bevel gears. It has 12 teeth and is more compact than the crown gear. It is only

slightly more efficient, and can also be used in the Differential (three bevel

gears are the only gears that fit inside it).

- Two bevel gears meshed at right angles.

|

|

Worm

Gear Worm

Gear

This gear is very unusual, but also very useful. For one full rotation of the

worm gear, the gear that it is meshed with will move along one tooth. For example,

the model on the left reduces the speed of the gear by 24:1 - a very compact and

efficient way of gear reduction. Another bonus is that it is a one way function

only, no amount of turning will make you turn it the other way (a useful feature

in cranes, for example), although it will wiggle slightly as the size of the gear

is just smaller than 2 large bushings. This wiggle can be eliminated by positioning

the worm gear vertically in a structure.

- A small structure connecting a worm gear and 24-toothed gear

|

|

The

Rack The

Rack

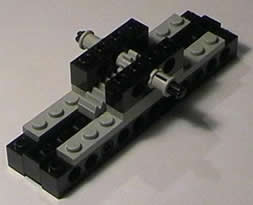

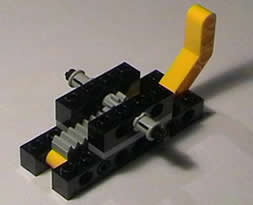

The rack is a small, flat gear the size of a 4x1 brick. It can be used to convert

gears into linear movement and is often used in car mechanisms. The rack must

be able to slide freely, and there are generally three options for this. Up-turned

beams (on the left), half beams (picture below) or smooth tiles. My technic Lego

doesn't include any smooth tiles (and I cannot be bothered to get some from my

other Lego to combine it) so I do not have an example of this. You must make sure

that the cog is raised sufficiently from the edges of the rack otherwise the rack

will not slide properly. That cog can be any sort of cog, but to make the structure

more compact and to allow finer control, an 8-toothed cog is normally used.

It will not take much turning to get the rack out of the mechanism, so longer

racks can be made by joining them together at the bottom.

- (above) A rack sliding on upturned beams

- A rack sliding on a yellow half beam (it that its name???)

|

|